Call: 08045815364

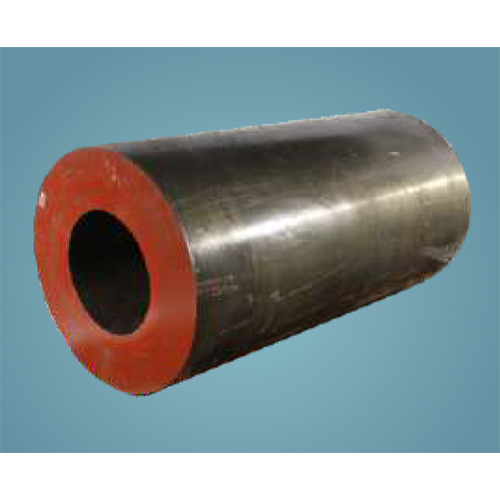

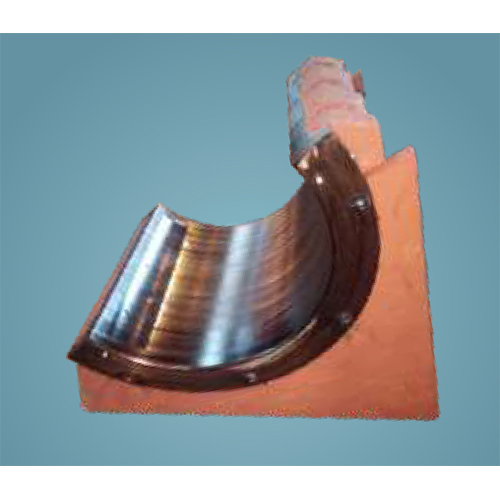

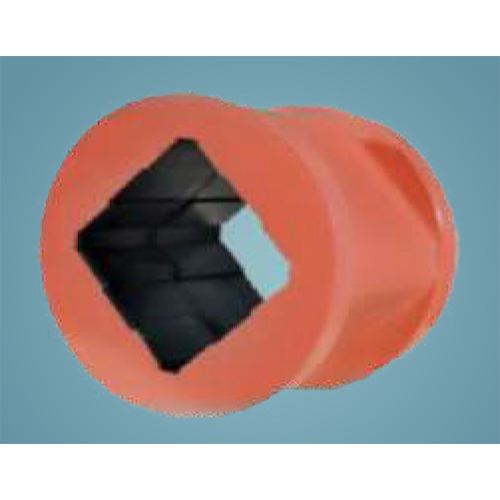

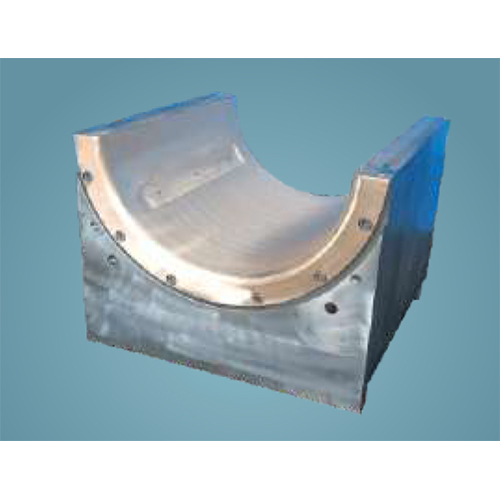

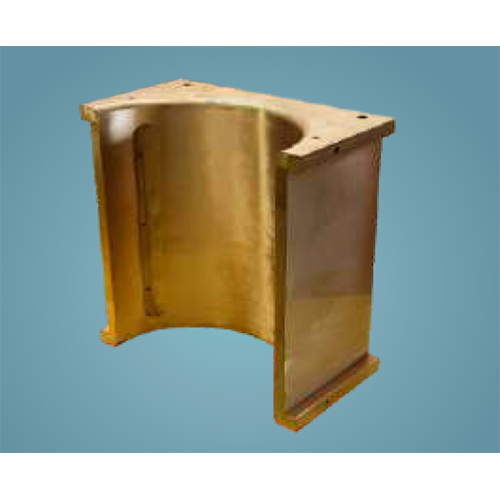

Durable and Trusted Tractor Trailers, Sugar Mills Spares, Mill Spares, Bronze Products, Chains & Slats, etc.

- New Arrivals

- Featured

Kolhapur Auto Works Pvt. Ltd. is a notable Manufacturer, Supplier and

Exporter of high-quality Tractor Trailers, Sugar Mills Spares, Mill

Spares, Bronze Products, Chains & Slats, etc. We are an ISO 9001:

2015 certified company. Founded in 1933 by the visionary Late Shri

Mahadba Mestri in Udyamnagar, Kolhapur, Kolhapur Auto Works (KAW) has

evolved into an industry leader. As Indias first developer of the

indigenous Coal Gas Plant and creator of the iconic Vishwas Oil Engine,

Shri Mestri earned the title Yantra Maharshi in recognition of his

engineering brilliance. His legacy was upheld by Late Shri Panditrao

Shelke, whose steadfast pursuit of excellence continues to shape our

organization.

Today, KAW operates from a cutting-edge 60,000 sq ft facility, combining a highly capable machine shop and foundry. Our specialized infrastructure and skilled workforce enable us to serve a global clientele across various industries including Sugar, Cement, Mining, and more.

Our Capabilities & Engineering Expertise

Utilizing the latest CAD/CAM tools and a Concurrent Engineering approach, we ensure precision and productivity across design, simulation, and drafting. Our in-house pattern shop, advanced casting unit, and CNC/VMC machining facilities support end-to-end manufacturingfrom raw material to finish. Dedicated quality assurance teams perform rigorous inspections throughout the production lifecycle, ensuring all parts meet engineering standards and customer specifications before dispatch.

Our Vision

To deliver exceptional products that drive value for our customersanchored by innovation, teamwork, and continuous improvement.

Our Quality Policy

Every project is overseen by qualified engineers who develop bespoke QA plans, guaranteeing excellence from concept through to final delivery.

Industries We Serve

We provide specialized engineering solutions tailored to diverse sectors, including:

Our customized spares, machinery, and services cater to the unique demands of each field.

Our Growth Journey

Milestones & Client Success

Our Development Process: Precision in Every Step

At Kolhapur Auto Works Pvt. Ltd., our manufacturing excellence is built on a streamlined and integrated development process. From initial design to final dispatch, every phase is meticulously executed to deliver products that meet the highest standards of quality and performance.

1. Design & Simulation

We begin with an advanced design process powered by Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) tools. These systems, part of our Advanced Engineering Environments (AEEs), enable our engineers to simulate, analyze, and refine designs digitallyensuring maximum efficiency, precision, and cost-effectiveness right from the concept stage.

2. Pattern Development

Our in-house pattern shop gives us a distinctive advantage. Staffed with experienced draftsmen and artisans, the unit produces highly accurate patterns with tight dimensional tolerances. This ensures seamless alignment between design and final production, reducing errors and improving overall quality.

3. Casting Process

The casting division is equipped with modern heat treatment facilities, precision equipment, and a rigorous quality control framework. Whether it's for ferrous or non-ferrous components, our setup ensures consistency, strength, and optimal performance of all cast products.

4. Machining Process

To complement our casting operations, we operate a fully integrated machine shop featuring:

This allows us to provide components in either fully finished or semi-finished condition, based on client requirements. Our setup supports complex geometries and high-volume demands with equal efficiency.

5. Pre-Dispatch Inspection

Before any product leaves our facility, it undergoes a multi-stage inspection process by our dedicated quality assurance team. Each item is thoroughly tested against customer specifications and industry benchmarks to ensure flawless delivery.

Kolhapur Auto Works Pvt. Ltd. maintains a holistic, quality-driven development cyclefrom concept to completionensuring unmatched reliability, precision, and customer satisfaction with every product we deliver.

Today, KAW operates from a cutting-edge 60,000 sq ft facility, combining a highly capable machine shop and foundry. Our specialized infrastructure and skilled workforce enable us to serve a global clientele across various industries including Sugar, Cement, Mining, and more.

Our Capabilities & Engineering Expertise

Utilizing the latest CAD/CAM tools and a Concurrent Engineering approach, we ensure precision and productivity across design, simulation, and drafting. Our in-house pattern shop, advanced casting unit, and CNC/VMC machining facilities support end-to-end manufacturingfrom raw material to finish. Dedicated quality assurance teams perform rigorous inspections throughout the production lifecycle, ensuring all parts meet engineering standards and customer specifications before dispatch.

Our Vision

To deliver exceptional products that drive value for our customersanchored by innovation, teamwork, and continuous improvement.

Our Quality Policy

Every project is overseen by qualified engineers who develop bespoke QA plans, guaranteeing excellence from concept through to final delivery.

Industries We Serve

We provide specialized engineering solutions tailored to diverse sectors, including:

- Sugar

- Mining

- Cement

- Power & Energy

- Steel & Metallurgy

- Transportation

- Abrasives & Machinery

Our customized spares, machinery, and services cater to the unique demands of each field.

Our Growth Journey

- 1996 First exports to Africa, marking our global entry with sugar mill machinery

- 2016 Launched non-ferrous foundry for in-house engineering and casting

- 2021 Formed global partnership with Chang Tractors, Thailand; KAW becomes a Pvt. Ltd.; expanded to Gokul Shirgaon MIDC; upgraded CNC infrastructure

- 2025 Introduced Moto Division and MotoHaus for the automotive aftermarket

Milestones & Client Success

- 2,768+ projects completed in the past five years

- 568+ clients served worldwide, reflecting trust in our consistency and quality

Our Development Process: Precision in Every Step

At Kolhapur Auto Works Pvt. Ltd., our manufacturing excellence is built on a streamlined and integrated development process. From initial design to final dispatch, every phase is meticulously executed to deliver products that meet the highest standards of quality and performance.

1. Design & Simulation

We begin with an advanced design process powered by Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) tools. These systems, part of our Advanced Engineering Environments (AEEs), enable our engineers to simulate, analyze, and refine designs digitallyensuring maximum efficiency, precision, and cost-effectiveness right from the concept stage.

2. Pattern Development

Our in-house pattern shop gives us a distinctive advantage. Staffed with experienced draftsmen and artisans, the unit produces highly accurate patterns with tight dimensional tolerances. This ensures seamless alignment between design and final production, reducing errors and improving overall quality.

3. Casting Process

The casting division is equipped with modern heat treatment facilities, precision equipment, and a rigorous quality control framework. Whether it's for ferrous or non-ferrous components, our setup ensures consistency, strength, and optimal performance of all cast products.

4. Machining Process

To complement our casting operations, we operate a fully integrated machine shop featuring:

- Conventional machines

- CNC/VMC systems

- Specialized lathes

- Custom-purpose machines

This allows us to provide components in either fully finished or semi-finished condition, based on client requirements. Our setup supports complex geometries and high-volume demands with equal efficiency.

5. Pre-Dispatch Inspection

Before any product leaves our facility, it undergoes a multi-stage inspection process by our dedicated quality assurance team. Each item is thoroughly tested against customer specifications and industry benchmarks to ensure flawless delivery.

Kolhapur Auto Works Pvt. Ltd. maintains a holistic, quality-driven development cyclefrom concept to completionensuring unmatched reliability, precision, and customer satisfaction with every product we deliver.

Send Inquiry

Send Inquiry